Type R Trophy Build – 2020

Our Type R Trophy Build for 2020 is now Complete.

The car started off life as a 2004 EP3 Civic Type R Track Car that had a few modifications but none that would be beneficial for us and what we want to achieve with the car. Having already built two Type R Trophy cars for customers both of which were race winners in 2019 we wanted to build this one for ourselves to see if we could create what we would class as the perfect Type R Trophy Build.

With budget in mind and not wanting to price the build out of reach of potential first time racers we set about stripping the car down so we could see what we had to work with. The car itself was in good condition with general surface rust in the wheel arches that is seen on all these cars but no nasty surprises which can quite often be found on a 16 year old road car.

The car was set to built to the highest specification there can be within the tightly controlled type R trophy regulations. We can build one of these cars with a customer supplied base car from around £7500,00 by just bolting the regulation parts on with no refreshing of bearings, calipers or any other common parts found to fail on these cars. This car however we wanted to show how we believe they should be built to create a reliable, well presented race car that will last many years to come.

With the car stripped down we set about tackling the wheel arches and removing all the underseal and surface rust before treating the areas with rust prevention and primer. The inside of the car had the cage installed and then removed ready for it’s trip to the bodyshop for a fresh coat of paint.

Images showing the car prepared for the bodyshop

With the car returned from the bodyshop with a immaculate coating of Satin Silver it was time to go ahead with assembly. We reinstalled our freshly prepared internal wiring loom and we then set about installing the Safety Devices MSA Approved Roll Cage, Harness Points and other safety features such as the OMP Black Series Fire Extinguisher, Tegiwa Fixed Bucket Seat Mounts and Corbeau Harnesses and Seat.

The Steering lock was removed along with a MSA Kill Switch Fitted and Pull Cables for External operation of both the Kill Switch and Extinguisher. We also installed a Personal 330mm Suede Steering Wheel along with a NRG Quick Release.

In terms of finishing the interior off nicely we re-installed the centre plastics and Handbrake as the weight of them is minimal and Type R Trophy stipulates a minimum weight the cars have to be after a race so it wasn’t something of concern adding the extra Kilo of plastics to give a nice finish to the centre of the interior. We then set about making the door cards pleasing to the eye with a mix of ABS Gloss black plastic and modifying the OEM door card by removing the Top section for the door lever.

Moving forward we set about making the Engine and Gearbox reliable with a Clockwise Motion Sump Baffle to stop unwanted Oil Surge, Replacement of various pulleys, tensioners and belts that are known common faliures. The engine received a fresh genuine Honda Timing Chain, Tensioner and Guides, NGK iridium Plugs and Motul Fluids.

With the gearbox removed we then set about making sure this remains reliable being another common problem we see day in day out in our Workshop. The MFactory Race Pack Stage 1 LSD was installed as per regulations, new Genuine Honda Bearing Set installed into the casings along with new Genuine Honda Synchros throughout the Gearset. With all that work done and completed we installed a new Exedy OEM clutch kit and OEM Facelift flywheel and attached the Gearbox back onto the Engine.

Following on from the above we then set about installing the permitted Engine Performance Parts in the form of a Tegiwa 70mm Exhaust, Tegiwa CAT Downpipe and Tegiwa Carbon Airbox. With this being a budget series the regulations restrict any further engine modifications keeping it tight, fair and controlled for all.

Finally after the above is complete we set about installing the suspension and brake components.

We had all the arms removed from the car, Blasted and Zinc plated giving a fantastic durable hard finish that will withstand any heat thrown at it from the brakes. The suspension arms and uprights are then fitted with the Regulation Superpro Type R Trophy Bush Kit and New Wheel Bearings Front and Rear. Along with the YellowSpeed Premium Competition Coilovers, Roll Centre adjusters, 24mm Rear Roll bar Kit and Tegiwa Camber arms, these components are then all bolted to the car with freshly zinc plated bolts and copper grease ensuring the car is extremely easy to work on in future.

Finally we moved onto fitting the stopping power. This comes in the form of our tried and tested formula of PBS Brakes Pads, Pagid Brake Discs, HEL braided brake lines and Motul Brake Fluid. With the brakes and calipers installed it was time to fit the freshly wrapped Rota Force Wheels with Nankang AR1 Tyres and send the car off to be wrapped in our current car design used on all our builds.

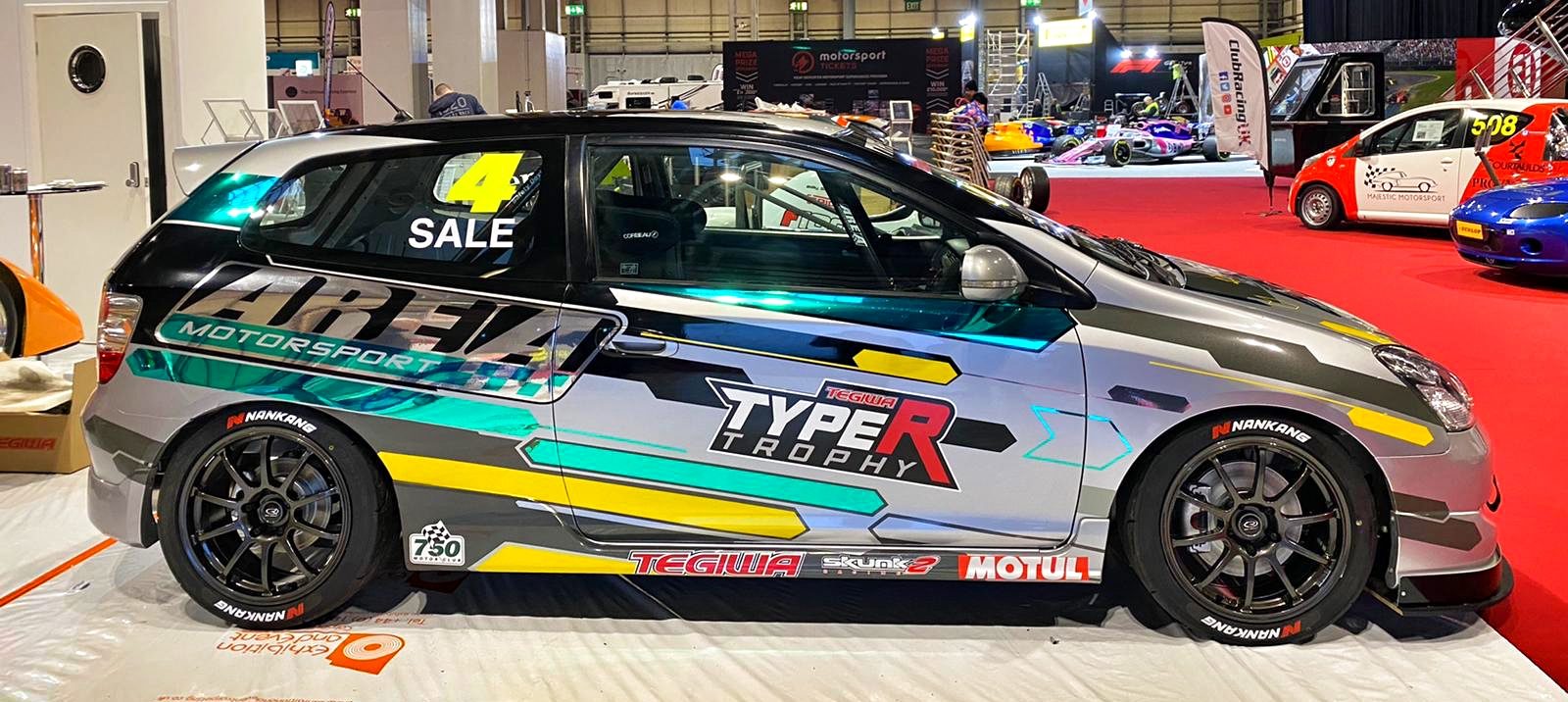

Completed images of the car can be seen below. We hope you’ve enjoyed our first in depth blog post on our first for 2020 Type R Trophy car.